Complete Sheet Metal Fabrication. One Supplier, Zero Hassle

Stop coordinating multiple vendors for cutting, bending, welding, and finishing. Get integrated manufacturing with automotive-grade quality from a single ISO-certified facility.

40+ Years

Manufacturing Experience

Triple ISO

9001 + IATF 16949 + 14001

150M+ Parts

Annual Capacity

Leading companies we support

Sheet Metal Fabrication Capabilities

Our capabilities are built to reduce rework, delays, and assembly risks

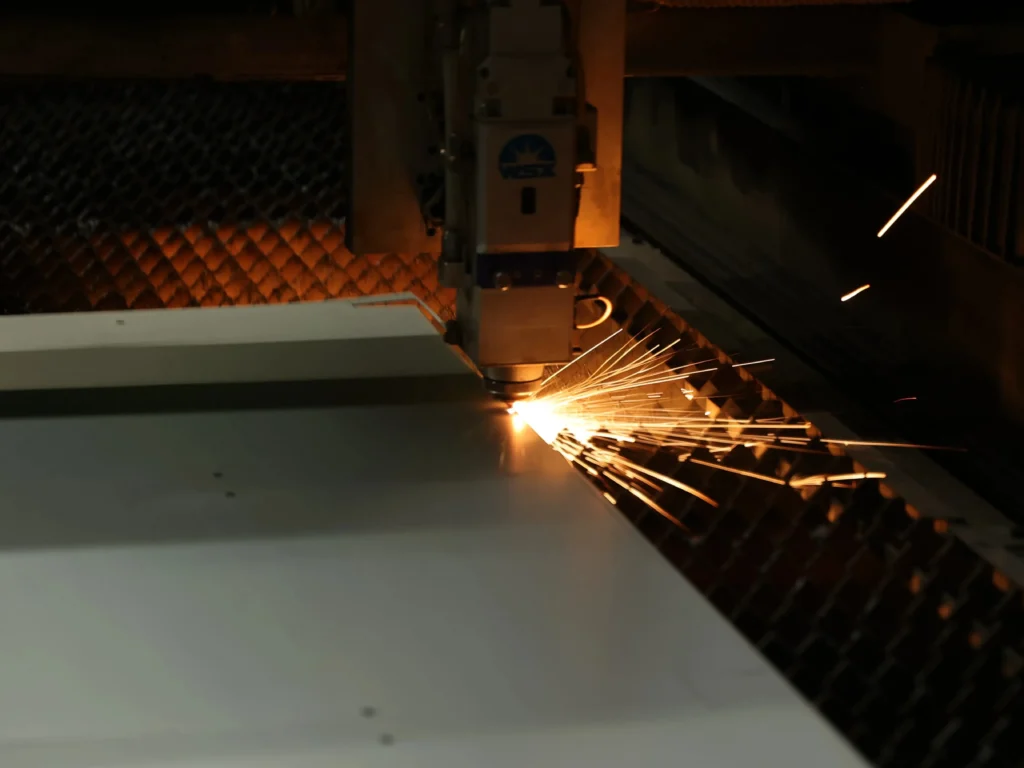

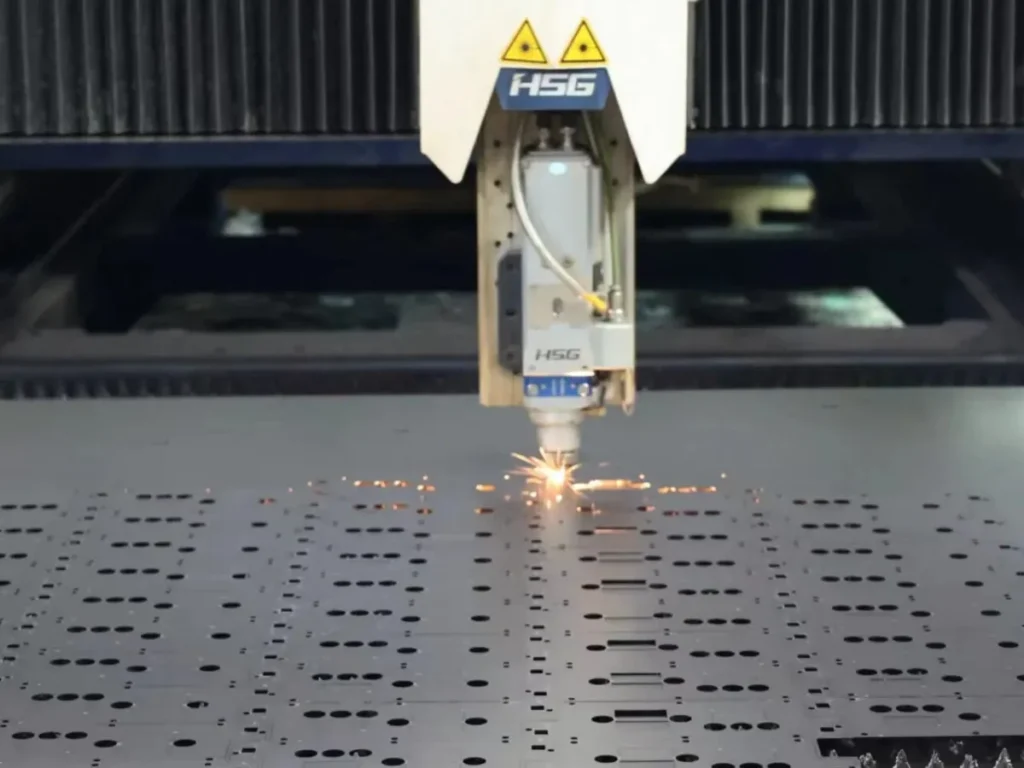

Precision Laser Cutting

Our state-of-the-art laser cutting systems deliver precise cuts with minimal material waste. Capable of handling materials up to various thicknesses, our laser technology produces clean edges and intricate details with exceptional repeatability.

- Precision cuts with minimal burrs

- No tool wear or setup time

- Suitable for prototypes and production

CNC Punching

Our CNC punching equipment delivers rapid, accurate hole and shape punching with exceptional consistency. Ideal for high-volume production, it reduces lead times while maintaining tight tolerances. We maintain a comprehensive library of punch tools and can develop custom tooling for specialized requirements.

- Rapid production cycles

- Consistent hole placement and sizing

- High-volume efficiency

- Custom tooling available

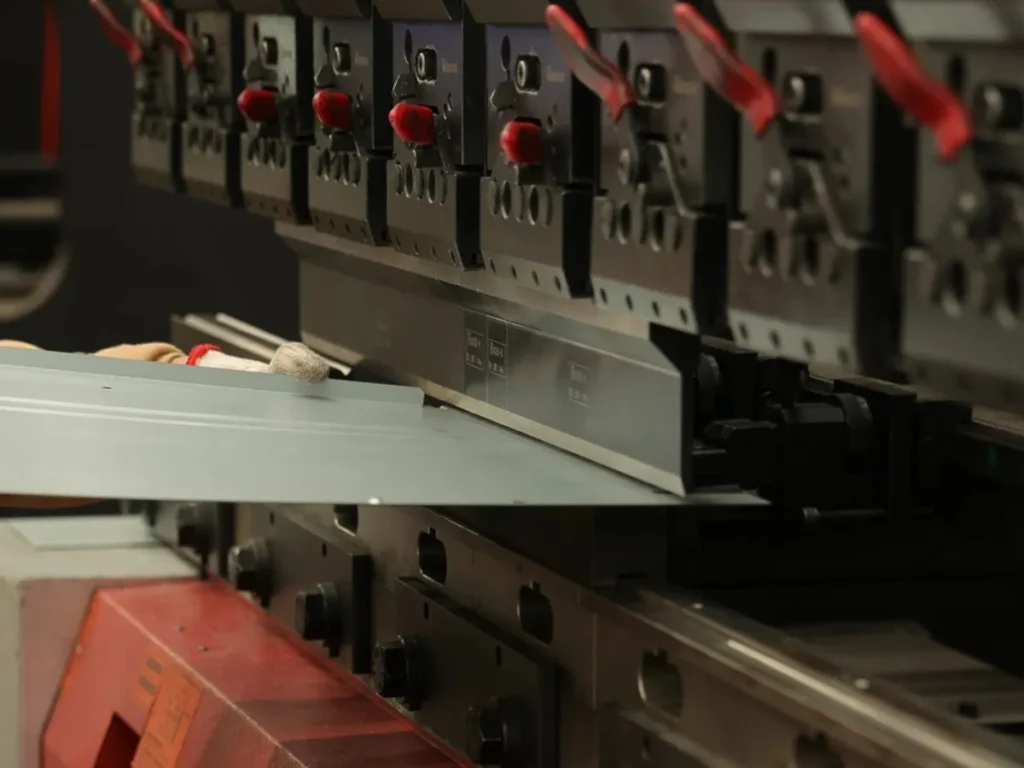

Complex Bending with Precision

Our hydraulic and CNC bending equipment handles simple to complex geometries with precision angle control. We achieve bends within ±1 degree accuracy, enabling intricate 3D shapes from flat sheet stock. Whether you need single bends or multi-directional forming, our experienced operators ensure consistent results across your entire production run.

- Precision angle control (±1°)

- Complex multi-directional bending

- Minimal springback

- •Custom die tooling available

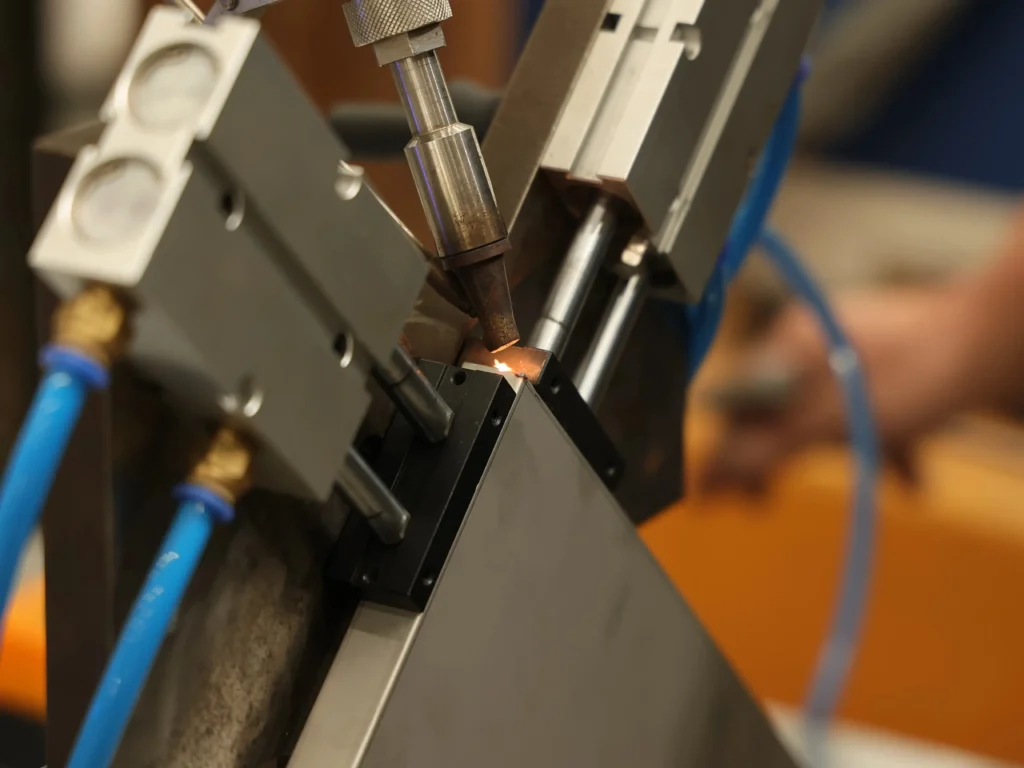

Multi-Process Welding

ZAKFAB offers comprehensive welding services including MIG, TIG, and spot welding. Our certified welders combine traditional craftsmanship with modern quality control to produce strong, reliable welds. All welds undergo rigorous inspection and testing to ensure structural integrity and compliance with industry standards

- Multiple welding processes

- Certified welders

- Quality inspection included

- Suitable for various materials and applications

Comprehensive Surface Finishing

From powder coating and anodizing to plating and polishing, ZAKFAB offers a complete range of surface finishing options that enhance durability and aesthetics. Whether you need functional protection or cosmetic enhancement, we have the expertise and equipment to deliver.

- Powder coating

- Anodizing

- Electroplating

- Polishing

- Brushing

- Protective coating

Complete Assembly Services

Beyond individual components, ZAKFAB provides comprehensive assembly services. We can integrate multiple parts, install fasteners, add electrical components, and perform final quality checks. This end-to-end solution reduces your assembly burden and ensures perfect fit and function.

- Multi-component assembly

- Hardware installation

- Electrical integration

- Functional testing

Sheet Metal Products We Manufacture

ZAK produced many kinds of custom sheet metal parts and products for different industry applications including electrical enclosures, control cabinets, metal housings, server cases, frames, brackets, panels, covers & plates. Here are some of our work for your reference.

Stainless Steel Electrical Enclosures

Premium corrosion-resistant electrical enclosures for harsh environments. Ideal for outdoor, coastal, and chemical applications.

- 304/316 Stainless Steel

- IP65/IP67 Rating Available

- Custom Surface Finishes

- NEMA/UL Standard

Double Door Electrical Enclosures

Large-capacity enclosures with synchronized double doors for easy access and maintenance of complex systems.

- Synchronized Locking

- Easy Maintenance Access

- Customizable Interior

- All Material Options

Carbon Steel Electrical Enclosures

Heavy-duty carbon steel enclosures for demanding industrial applications. Available with various coating options.

- High Strength Design

- Powder Coat/Paint Options

- Custom Dimensions

- Welded Construction

Stainless Steel Cabinets

Multi-purpose stainless steel storage for food, pharma, and industrial facilities. 304/316 grades, fully welded construction, adjustable shelving up to 50kg per shelf

- Versatile applications (food, pharma, industrial)

- High durability and corrosion resistance

- Cost-effective solution

- Quick turnaround

Laboratory Cabinets

Precision laboratory cabinets for pharmaceutical R&D and medical device testing. Electropolished 304 stainless steel, cleanroom-compatible.

- Specialized for regulated industries (pharma, medical)

- Highest hygiene and contamination control standards

- Premium precision engineering

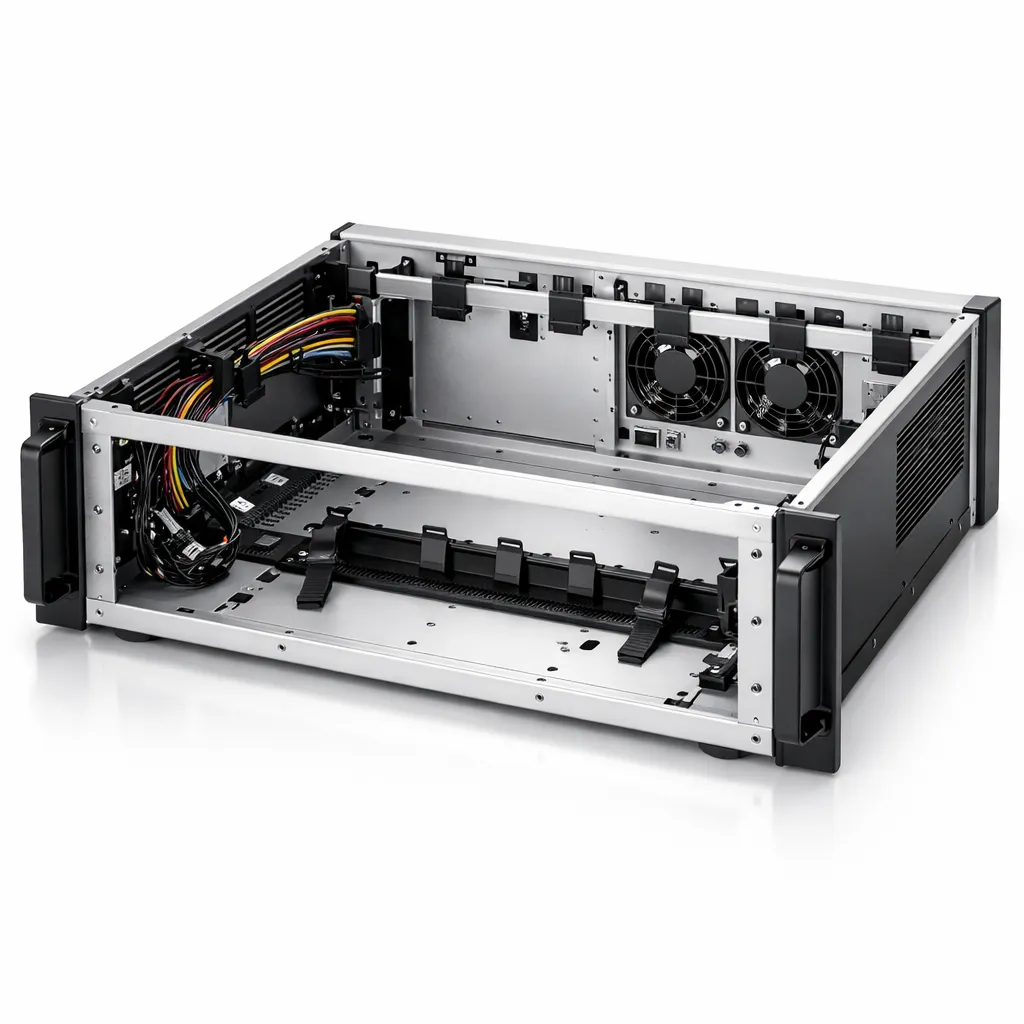

Rackmount Chassis/Server Case

Precision-engineered chassis for electronics, telecommunications, and industrial control systems with EMI shielding.

- EMI/RFI Shielding

- Precision Tolerances

- Custom Cutouts

- Rapid Prototyping

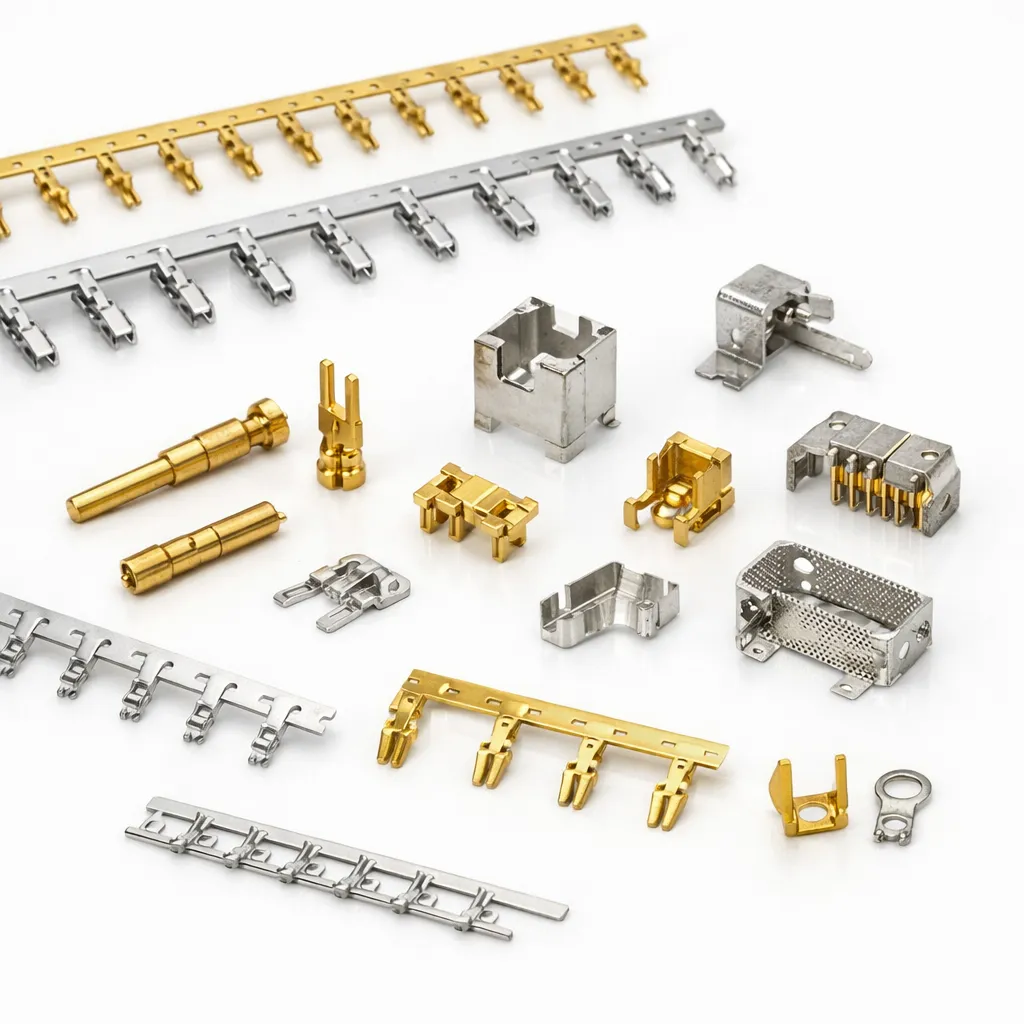

Electronic Connectors

Ultra-precision stamped connectors for electronics and telecommunications with multiple plating options and RoHS compliance.

- Ultra-Precision Tolerances

- Multiple Plating Options

- RoHS Compliant

- High-Speed Production

Consumer Product Components

High-volume stamped components for consumer electronics and appliances with cost optimization and rapid tooling.

- High-Volume Production

- Cost Optimization

- Rapid Tooling

- Quality Assurance

Surface Treatment & Coating

Comprehensive surface finishing including powder coating, anodizing, plating, and painting with 50+ color options.

- 50+ Color Options

- Multiple Coating Types

- Environmental Compliance

- Consistent Quality

Get Your Quote Now

Send us your requirements and we’ll respond within 24 hours with pricing, lead time, and DFM feedback.

By submitting this form, you agree to our Privacy Policy. We respect your data and will never share it with third parties.

Why Choose ZAK

500+ global leading companies trust us to deliver their parts on time with quality guaranteed, every time. Here’s why.

Integrated Manufacturing

From design consultation and tooling development to manufacturing and assembly, we control every step. Our integrated approach eliminates outsourcing delays and ensures consistent quality.

Engineering-First Approach

12 engineers (avg 11 years experience) review every project. Free DFM analysis catches problems early.

ISO & IATF Certified

We meet quality standards required by Honda, Toyota, VW. This discipline applies to every part we make.

40 Years expertise

Since 1985, ZAK has built a reputation for reliability, quality, and innovation. Our deep experience ensures you're working with true experts.

Design Optimization That Delivers Results

From concept to production, our engineering team ensures your designs are manufacturable, cost-effective, and compliant.

24-Hour DFM Analysis

Our engineers review your CAD files and provide detailed DFM analysis within 24 hours, identifying manufacturing challenges and cost-saving opportunities before production begins.

Material & Process Optimization

We evaluate material options, thickness optimization, and manufacturing processes to reduce weight, minimize waste, and lower production costs without compromising quality.

Compliance & Quality Assurance

Our team ensures your designs meet ISO 9001, IATF 16949, and other industry standards. We provide comprehensive documentation and traceability support.

Ready to optimize your sheet metal design? Contact our engineering team today for a free DFM analysis and expert guidance.

How to Get Started

It is simple to work with ZAK, from initial inquiry to production delivery, we provides transparent communication and engineering support at every stage.

Quality Guaranteed

Our comprehensive quality control system ensures every part meets your exact specifications. From incoming material inspection to final assembly verification, we maintain ISO 9001 and IATF 16949 standards throughout the manufacturing process.

- Engineers with 11+ years average experience

- Quality checks at each process stage

- Advanced equipments ensure inspection accuracy

- 100% Inspection before shipment

- Full certified compliance with CE, ROHS, NEMA, UL standard

Industries We Serve

ZAK’s advanced sheet metal fabrication capabilities serve critical industries worldwide. Our expertise in precision engineering, quality assurance, and rapid prototyping makes us the trusted partner for complex manufacturing challenges.

Electrical & Electronics

Custom electrical enclosures, control panels, and distribution boxes engineered for safety, reliability, and compliance with international standards.

Automotive & Mobility

Precision-engineered sheet metal parts for automotive systems, vehicle components, and transportation equipment.

Industrial Equipment

Robust sheet metal components for industrial automation systems, machinery enclosures, and production equipment.

HVAC & Appliances

Custom ductwork, enclosures, and components for heating, ventilation, and air conditioning systems.

Telecommunications

High-performance chassis and equipment housings designed for telecommunications infrastructure and data center operations.

Energy & Power

Robust enclosures, inverter cases, control panels, and battery housings for power generation, distribution, and renewable energy applications.

Consumer Electronics

Precision sheet metal enclosures and components for consumer electronics, home appliances, and smart devices.

Laboratory & Commercial Cabinets

High-quality stainless steel cabinets and workstations for laboratory, pharmaceutical, food processing, and commercial kitchen applications.

What is Sheet Metal Fabrication?

Sheet metal fabrication is a precision manufacturing process that transforms flat metal sheets into complex components through cutting, forming, and assembly. From electrical enclosures to industrial equipment, it’s the ideal solution for parts requiring strength, durability, and cost-effectiveness.

- High strength and durability

- Cost-efficient manufacturing

- Flexible and customizable designs

- Scalable from prototype to mass production

- Lightweight yet structurally strong

- High precision with tight tolerances

Design Review

Review drawings for manufacturability

Catches issues early, reduces costly revisions

Material Selection

Source certified metals to spec

Ensures material traceability and compliance

Laser Cutting

Precision cutting to blueprint specs

Clean edges and accurate dimensions

Deburring

Remove sharp edges and burrs

Critical for safety and surface finish quality

CNC Bending

Form parts to exact angles

Repeatability across all production volumes

Welding

Join components structurally

Certified processes ensure joint integrity

Grinding & Surface Prep

Smooth weld seams and surfaces

Creates uniform surface for finishing

Surface Finishing

Apply protective coatings

Protects against corrosion and wear

QC & Assembly

100% inspection + hardware installation

Ship-ready parts, fewer suppliers to manage

Our Sheet Metal Fabrication Process

Our sheet metal fabrication process is a structured fabrication workflow designed to reduce your risk,

ensure part consistency, and deliver components that fit, assemble, and perform as intended. We have full capability of sheet metal fabrication, you can laser cutting, surface finish and assembly with us, our experienced engineers can also help you improve your design for manufacturity and save cost.

Our Sheet Metal Material Options

ZAK works with a diverse range of sheet metal materials to meet your specific application requirements. Each material has different grade and thickness to choose, our material expertise ensures your components perform reliably in any environment.

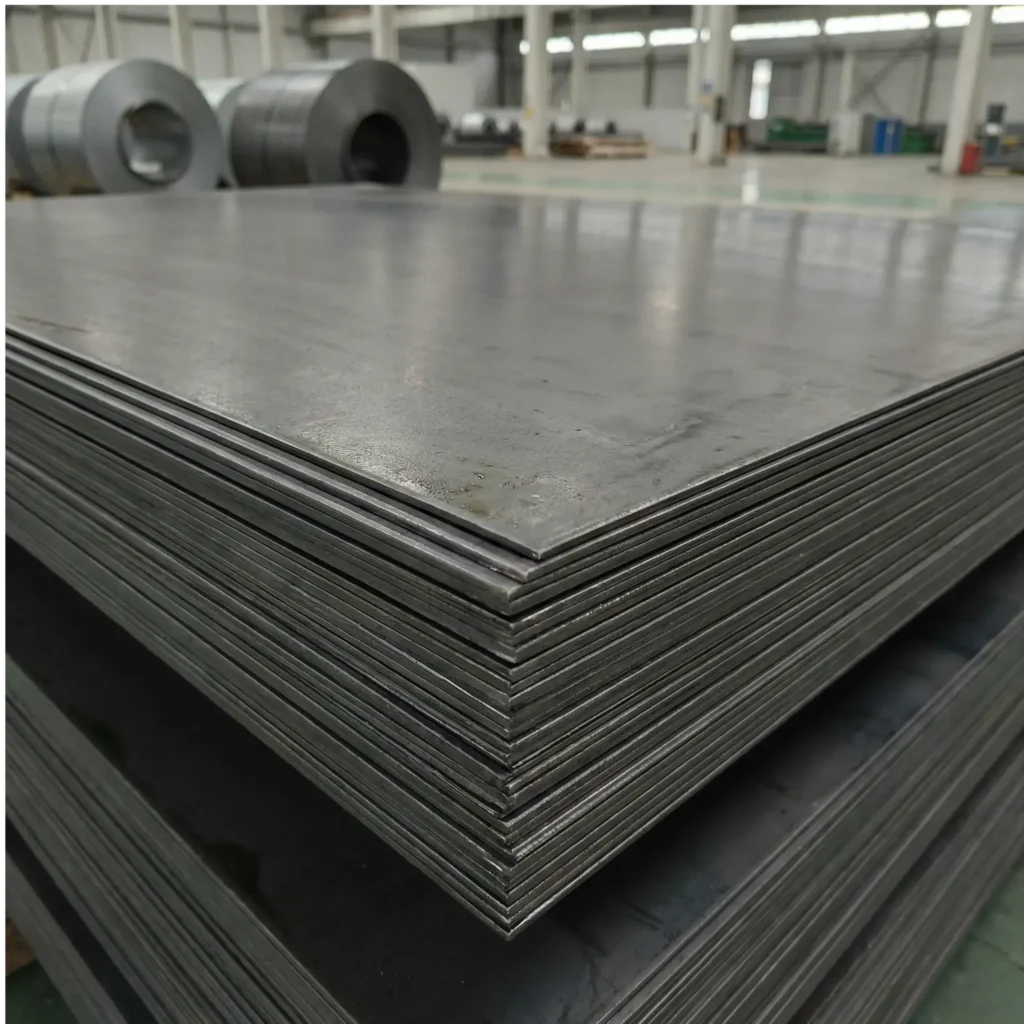

Carbon Steel

High strength, cost-effective, ideal for structural components and heavy-duty applications

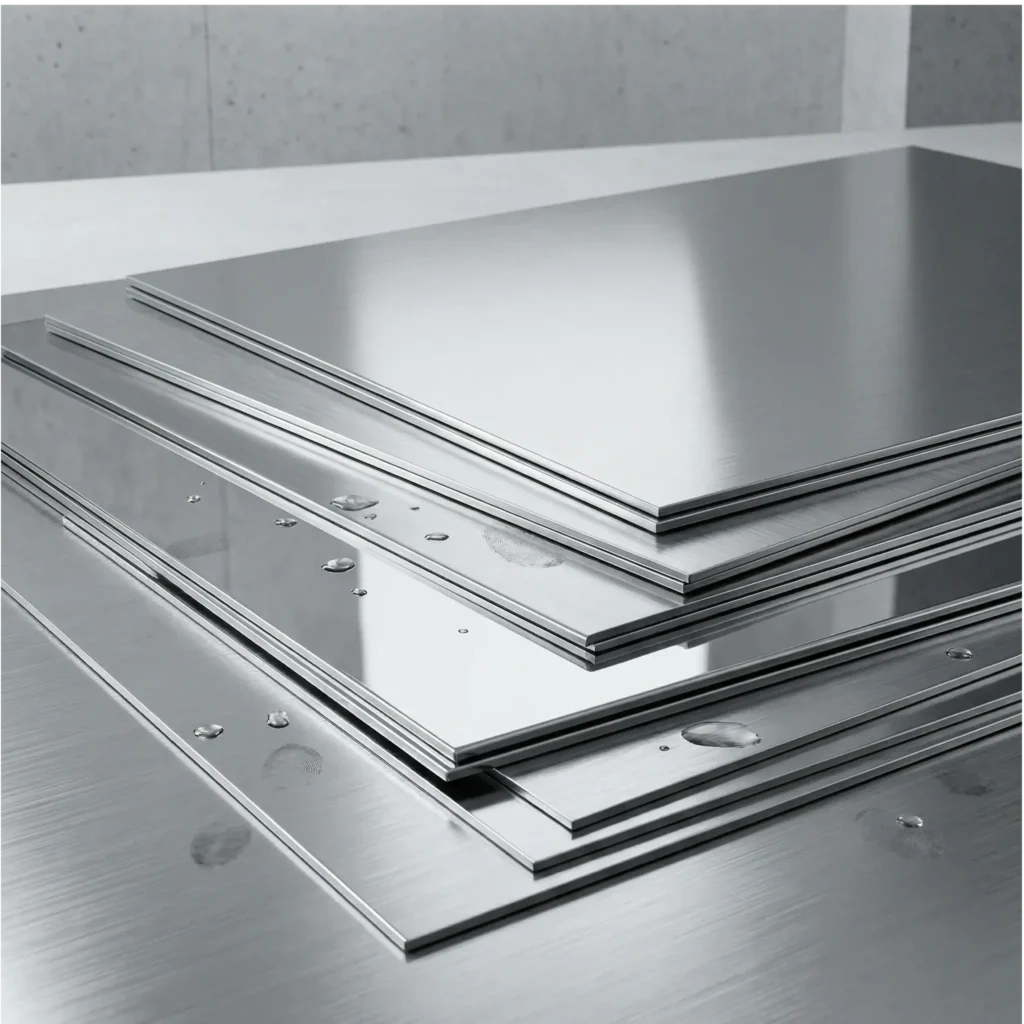

Stainless Steel

Corrosion-resistant, durable, perfect for food processing, medical, and outdoor applications

Galvanized Steel

Zinc-coated protection, excellent corrosion resistance, ideal for outdoor and harsh environments

Copper

Excellent electrical and thermal conductivity, ideal for electrical and heat transfer applications

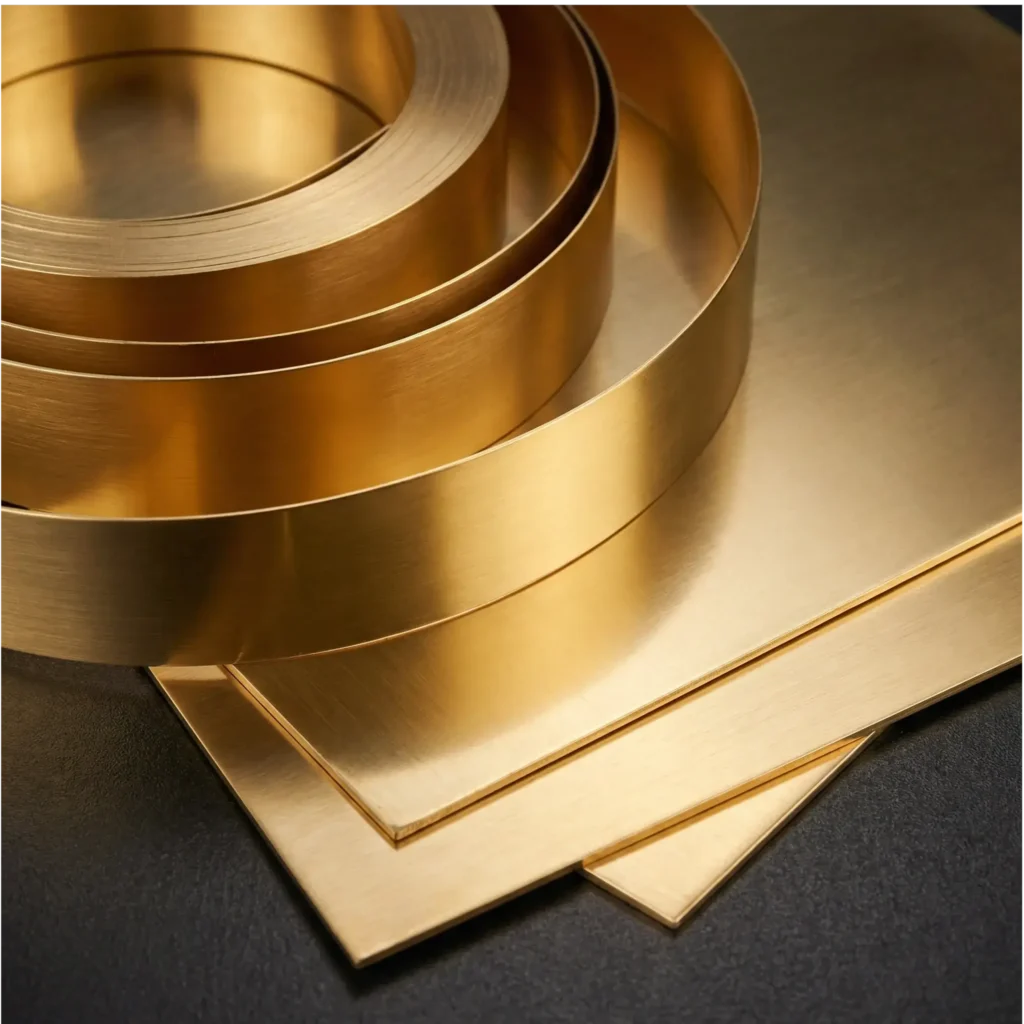

Brass

Corrosion-resistant, excellent machinability, ideal for decorative and functional components

Aluminum

Lightweight, excellent strength-to-weight ratio, ideal for aerospace and automotive industries

Sheet Metal Design Guidelines

Designing for manufacturability reduces costs, improves quality, and accelerates lead times. Our engineering team reviews every project for DFM optimization—but these guidelines help you create production-ready designs from the start.

Bend Radii

Minimum inside bend radius should equal material thickness for steel, 1.5× for aluminum to prevent cracking.

Hole-to-Edge Distance

Maintain minimum distance from hole edge to bend line to prevent distortion during forming.

Hole-to-Hole Spacing

Minimum spacing between holes prevents material deformation and ensures punch tool clearance.

Flange Height

Minimum flange height ensures proper forming without material tearing or springback issues.

Feature Proximity

Keep features (holes, slots, tabs) away from bends to maintain dimensional accuracy.

General Tolerances

Standard tolerances for laser cutting, bending, and assembled dimensions.

Standard Manufacturing Tolerances

The table below reflects our standard and precision capabilities. Standard tolerances apply unless tighter values are specified on your drawing. Tighter tolerances may increase cost and lead time — specify them only on functionally critical dimensions.

| Feature / Process | Standard Tolerance | Precision (on request) | Notes |

|---|---|---|---|

| Laser cutting — linear | ± 0.10 mm | ± 0.05 mm | For material thickness ≤ 3 mm |

| Laser cutting — hole diameter | ± 0.10 mm | ± 0.05 mm | Holes < 1 mm not recommended for laser |

| CNC punching — hole position | ± 0.10 mm | ± 0.05 mm | Relative to datum |

| Bending — angle | ± 0.5° | ± 0.25° | Springback varies with material and thickness |

| Bending — flange length | ± 0.20 mm | ± 0.10 mm | Measured from bend line to edge |

| Overall dimensions (< 300 mm) | ± 0.20 mm | ± 0.10 mm | Cumulative tolerance applies for multi-bend parts |

| Overall dimensions (300–1000 mm) | ± 0.30 mm | ± 0.15 mm | Use datum references for critical fits |

| Overall dimensions (> 1000 mm) | ± 0.50 mm | ± 0.25 mm | Large parts may require fixture verification |

| Flatness | 0.5 mm / 300 mm | 0.2 mm / 300 mm | After leveling; thin sheets may require fixturing |

| Hardware insertion position | ± 0.15 mm | ± 0.08 mm | PEM / clinch nuts, studs, standoffs |

| Welding distortion | ± 0.3–0.5 mm | ± 0.15 mm | Precision achievable with fixtures and laser welding |

| Powder coat thickness | 60–80 μm | 40–120 μm range | Adjustable per specification |

Frequently Asked Questions

Common questions from engineers and procurement teams about our sheet metal fabrication services.

Don't See Your Question?

Our engineering team is ready to help.

- E-mail: sales@zakfab.com

- Phone: 0086 18666666666

- Response within 24 hours

What file formats do you accept for quoting?

+What is your minimum order quantity?

+What are your standard lead times?

+Do you provide surface finishing services?

+How do you ensure quality?

+What is the maximum part size?

+What materials do you work with?

+Do you offer design assistance or DFM review?

+Can you handle both prototyping and volume production?

+How do you handle shipping and export?

+Ready to Get Started?

Whether you have detailed CAD files or just a napkin sketch, we’re ready to help bring your project to life. Start with a quote request, or schedule a call to discuss your requirements.