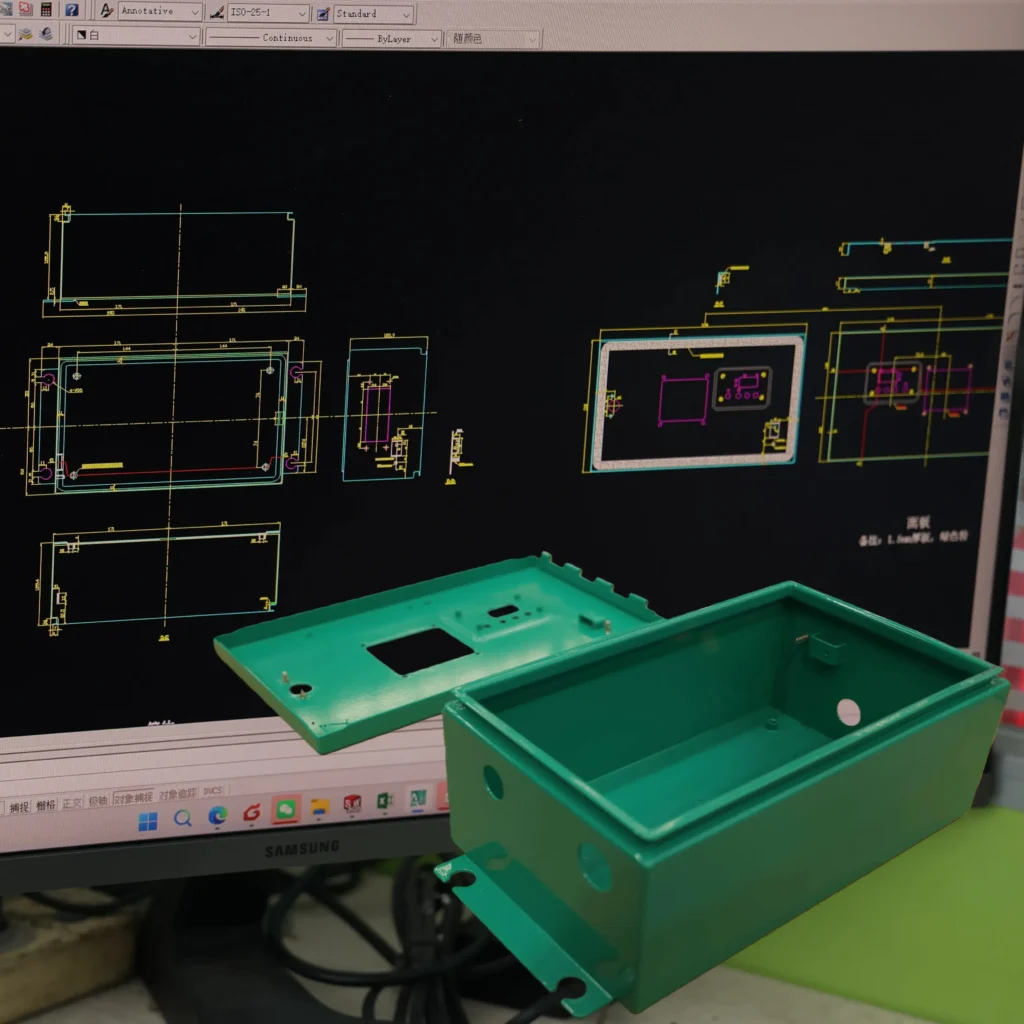

From Prototyping to Production

Sheet Metal EnclosuresPrecision Stamping Parts

Lower your costs. Speed up production. Get consistent quality.

We handle everything from tooling to finishing—so you don’t have to.

- 40+ Years Manufacturing Excellence

- ISO & IATF Certified (9001 | 14001 | 16949)

- Complete In-House Capabilities

- Free DFM & Engineering Support

Trusted by Leading Companies Worldwide

Complete Metal Manufacturing

From design support to finished parts, ZAK handles every step with sheet metal fabrication, precision stamping, tooling, welding, finishing, and assembly integrated under one roof.

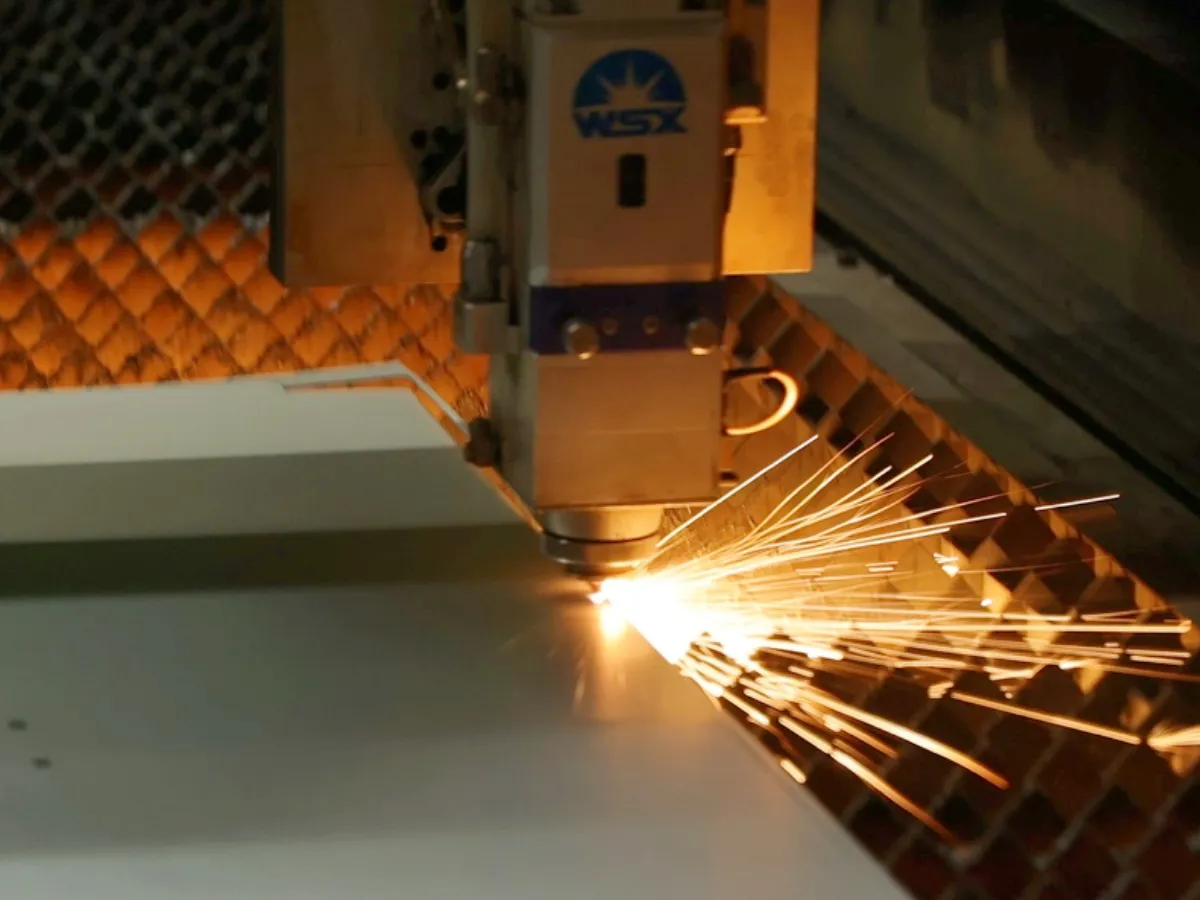

Sheet Metal Fabrication

Custom Enclosures & Structural Components

From large electrical enclosures to precision metal boxes—we cut, bend, weld, and assemble to your exact specifications.

Metal Stamping

High-Volume Precision Components

100+ stamping presses (110T-1200T) produce 150M+ parts annually with ±0.05mm tolerance—in-house tooling cuts lead times 40%.

Surface Finishing

Professional Appearance & Long-Term Protection

Every part leaves our factory finished to your standards—Powder coating, anodizing, e-coating, silk screening, polishing, or custom treatments.

Projects We Made Recently

ZAK produced many kinds of custom sheet metal parts and stamping components for different industry applications including electrical enclosures, control cabinets, metal housings, server cases, stamping frames, brackets, panels, covers & plates. Here are some of our work for your reference.

Stainless Steel Electrical Enclosures

Premium corrosion-resistant electrical enclosures for harsh environments. Ideal for outdoor, coastal, and chemical applications.

- 304/316 Stainless Steel

- IP65/IP67 Rating Available

- Custom Surface Finishes

- NEMA/UL Standard

Double Door Electrical Enclosures

Large-capacity enclosures with synchronized double doors for easy access and maintenance of complex systems.

- Synchronized Locking

- Easy Maintenance Access

- Customizable Interior

- All Material Options

Carbon Steel Electrical Enclosures

Heavy-duty carbon steel enclosures for demanding industrial applications. Available with various coating options.

- High Strength Design

- Powder Coat/Paint Options

- Custom Dimensions

- Welded Construction

Stainless Steel Cabinets

Multi-purpose stainless steel storage for food, pharma, and industrial facilities. 304/316 grades, fully welded construction, adjustable shelving up to 50kg per shelf

- Versatile applications (food, pharma, industrial)

- High durability and corrosion resistance

- Cost-effective solution

- Quick turnaround

Laboratory Cabinets

Precision laboratory cabinets for pharmaceutical R&D and medical device testing. Electropolished 304 stainless steel, cleanroom-compatible.

- Specialized for regulated industries (pharma, medical)

- Highest hygiene and contamination control standards

- Premium precision engineering

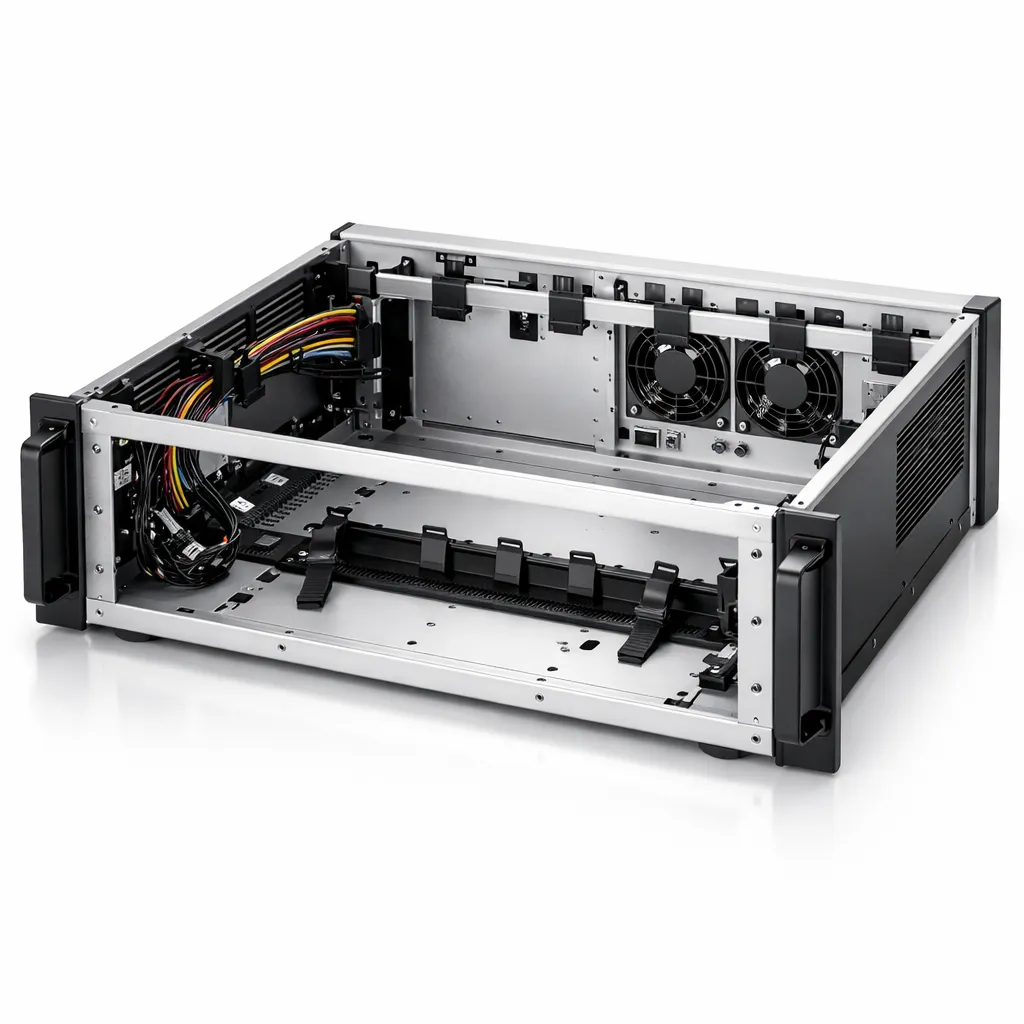

Rackmount Chassis/Server Case

Precision-engineered chassis for electronics, telecommunications, and industrial control systems with EMI shielding.

- EMI/RFI Shielding

- Precision Tolerances

- Custom Cutouts

- Rapid Prototyping

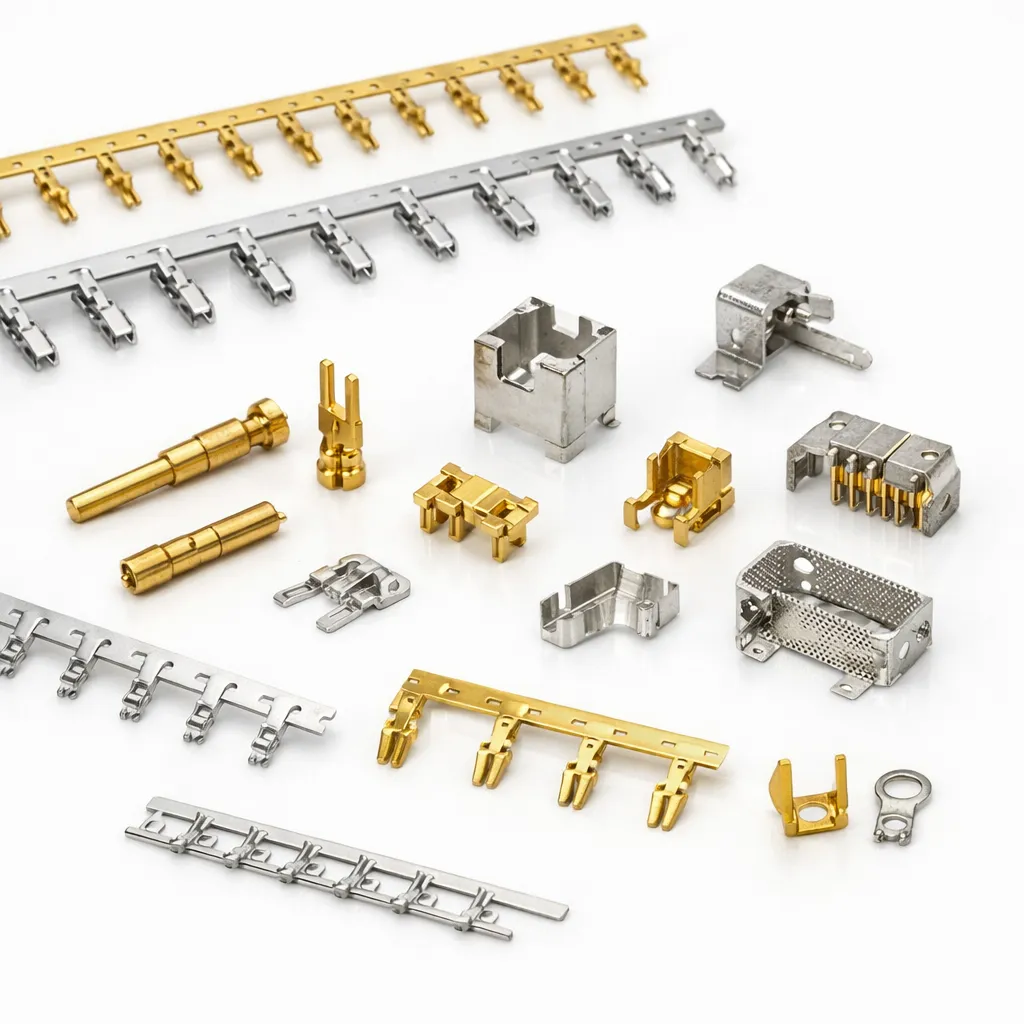

Electronic Connectors

Ultra-precision stamped connectors for electronics and telecommunications with multiple plating options and RoHS compliance.

- Ultra-Precision Tolerances

- Multiple Plating Options

- RoHS Compliant

- High-Speed Production

Consumer Product Components

High-volume stamped components for consumer electronics and appliances with cost optimization and rapid tooling.

- High-Volume Production

- Cost Optimization

- Rapid Tooling

- Quality Assurance

Surface Treatment & Coating

Comprehensive surface finishing including powder coating, anodizing, plating, and painting with 50+ color options.

- 50+ Color Options

- Multiple Coating Types

- Environmental Compliance

- Consistent Quality

One Facility. Complete Capabilities.

Zero CoordinationHeadaches.

Most metal fabricators outsource finishing, assembly, or tooling, which creates delays and quality gaps you have to manage.

ZAK handles everything in-house: metal stamping, sheet metal fabrication, welding, powder coating, and final assembly. One partner. One quality standard. Faster time-to-market.

Your Design. Your Specs.

We Build It Exactly.

Every project is different. ZAK manufactures to YOUR specifications—custom shapes, sizes, thicknesses, tolerances, finishes and more. Our engineers can work from your drawings or help you develop designs from scratch.

- Custom Sizes

- Custom Shape

- Custom Thickness

- Custom Surface Finishes

- Your Drawings

- Tight Tolerance

- Custom Labeling

- Custom Packaging

Every Metal. Every Grade.

Matched to Your Requirements.

From carbon steel to stainless steel, aluminum to copper, we process a wide range of metals for our sheet metal fabrication and stamping. Each material is available in different grades and varieties. Tell us your application, and we’ll recommend the right material for performance, cost, and durability.

- Carbon Steel (SPCC, SPHC, Q235)

- Aluminum (5052, 6061)

- Copper & Brass

- Stainless Steel (304, 316, 430)

- Galvanized Steel (SGCC)

- Custom Sourcing available

Design Smarter,

Manufacture Better

Avoid costly mistakes. Reduce material waste. Get to production faster with free expert DFM support from our engineering team

Cost Reduction Analysis

Identify design changes that cut material waste and simplify tooling

Manufacturability Review

Optimize your design for faster, more reliable production

Material Selection Guidance

Choose the right material for performance, durability, and cost

24-Hour DFM Feedback

Get detailed engineering feedback within one business day—no waiting

Certified Quality Assurance at Every Step

From raw material verification to final shipment, our ISO-certified quality system ensures precision, reliability, and consistency for every component we deliver.

ISO 9001:2015

Quality Management

ISO 14001:2015

Environmental

IATF 16949:2016

Automotive Excellence

Industries We Serve

Electrical & Electronics

Custom electrical enclosures, junction boxes, metal housing and control cabinets for power distribution, control systems, and electrical devices.

Automotive & Mobility

Precision stamped components, brackets, and motor housings for vehicles and EV systems, manufactured to IATF 16949-level quality standards.

Industrial Equipment

Heavy-duty sheet metal parts, machine frames, brackets, and custom panels supporting automation, machinery, robotics, and production systems.

HVAC & Appliances

Sheet metal fabrication casings, covers, and structures for air conditioning, refrigeration, and home appliance equipment.

Telecommunications

Durable metal enclosures and mounting brackets for communication equipment, routers, and signal-control systems.

Energy & Power

Robust enclosures, inverter cases, control panels, and battery housings for power generation, distribution, and renewable energy applications.

Lighting

Metal parts and enclosures for LED fixtures, commercial lighting, and decorative luminaire assemblies.

Construction

Structural metal components, mounting systems, and hardware for building, industrial and construction applications.

Simple Process, Exceptional Results

Whether you need a custom enclosure prototype or mass production of precision metal parts, from initial inquiry to final delivery, we make the manufacturing process simple, fast, and reliable.

1

Send Your Inquiry

Share your project details, technical drawings (2D/3D), or specifications through our inquiry form. No account or complicated process required.

2

Get Free DFM Analysis

Our engineering team reviews your design for manufacturability, identifying potential improvements to optimize cost and quality before quotation.

3

Receive Detailed Quote

Get a transparent quote including tooling fees (if any), unit price, lead time, and shipping options. No hidden charges.

4

Prototype & Approval

We produce initial samples or prototypes for your approval. You can request modifications before moving to full production.

5

Production & Quality Control

Full-scale manufacturing begins with ISO-certified quality control at every stage. Real-time updates available throughout production.

6

Delivery & Support

Secure packaging and global shipping. We provide full documentation, inspection reports, and after-sales technical support.

What Our Clients Say

Trusted by leading companies worldwide

Ready to Start Your Project?

Fill out the form below and our team will respond within 24 hours with a Free professional DFM analysis.

By submitting this form, you agree to our Privacy Policy. We respect your data and will never share it with third parties.

- 24-Hour Response

- NDA Available

Frequently Asked Questions by Our Clients

Quick answers to common questions about working with ZAK

What is your minimum order quantity (MOQ)?

We have no minimum order quantity. Whether you need 1 prototype or 100,000 production parts, we can accommodate your order. Our flexible manufacturing capabilities allow us to serve both prototyping and high-volume production needs.

What is the typical lead time for sheet metal fabrication?

Prototypes typically take 7-15 days. Production orders vary based on quantity and complexity, but standard orders are usually 3-4 weeks. We provide detailed timelines in our quotes and can accommodate rush orders when needed.

What file formats do you accept?

We accept all major CAD formats including STEP, IGES, DWG, DXF, PDF, SolidWorks, AutoCAD, Pro-E, and UG. If you have technical drawings in any format, we can work with them.

What certifications do you have?

ZAK is ISO 9001:2015 (Quality Management), ISO 14001:2015 (Environmental Management), and IATF 16949:2016 (Automotive Quality) certified. We maintain rigorous quality standards suitable for automotive, aerospace, medical, and industrial applications.

Do you offer tooling services?

Yes, we have an in-house tool & die workshop that designs and manufactures custom molds and dies. This allows us to reduce tooling costs by up to 40% compared to external suppliers and significantly shorten lead times.

What materials can you work with?

We work with a wide range of materials including stainless steel (304, 316), aluminum (5052, 6061), cold-rolled steel, galvanized steel, copper, brass, and specialty alloys. We can recommend the best material for your application.

Do you ship internationally?

Yes, we ship to 50+ countries worldwide. We handle all export documentation and work with reliable freight forwarders to ensure secure delivery. We can arrange door-to-door delivery or ship to your designated freight forwarder.

Can you sign an NDA (Non-Disclosure Agreement)?

Absolutely. We understand the importance of protecting your intellectual property and designs. We’re happy to sign your NDA before you share any confidential information or technical drawings with us.

Manufacturing Resourcing

Add Your Heading Text Here

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Add Your Heading Text Here

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Add Your Heading Text Here

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.